Our Tech

Our Tech

What Makes Us Different

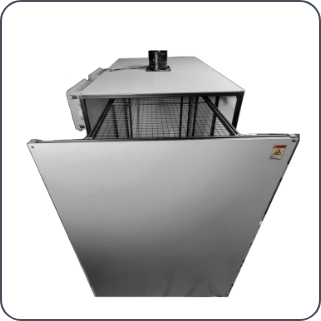

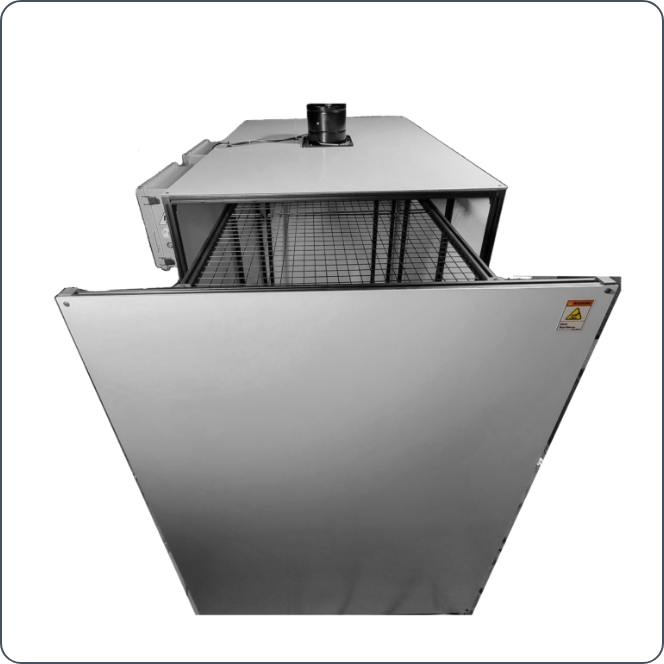

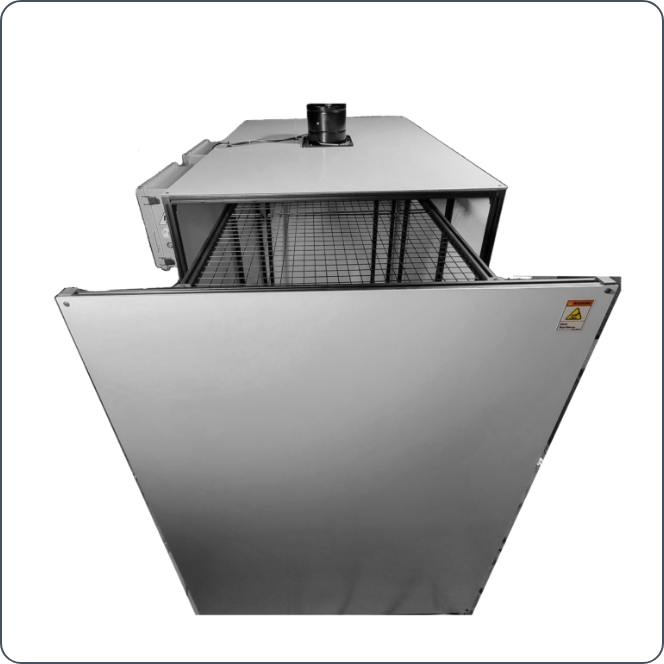

Curing has always been the bottleneck when it comes to Cerakote. Our innovative design significantly reduces the curing time and cost of operation. It also allows for curing of materials that previously could not be oven cured.

Our technology focuses all usable energy on the coating, not the air or substrate. This allows the curing process to take 1/8th of the time with the CERAKURE oven vs convection. By using penetrating waves that cure from the inside out, C-series Cerakote can now be oven cured.

CERAKURE is powered by 110v 20a and liquid propane. The cost of operation is greatly reduced from an electric oven.

Additive manufacturing no longer has to air dry. Items that once needed 5 days to completely cure now only need 45 minutes. Polymer can now be cured alongside metal. Since the substrate is not heated, the cool down time is 8 minutes.

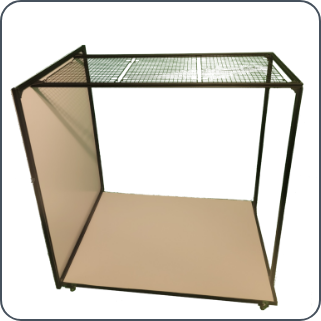

Combining a flash off rack into the door allows the user to only touch the parts once before curing. Multiple racks in rotation is the ideal setup.

Some of the industries who benefit from CERAKURE: DOD, Aerospace, Medical, Oil & Gas, Automotive, Golf, Fishing

Easy To Use

- 7″ HMI

- Simplified Controls

- Tack and Cure options

- Manual Exhaust control

- No Installation – Plug & Play

Innovative Design

- Roll out flash rack (can be purchased separately)

- Large interior 63 cubic feet

- Small exterior footprint

Cost Effective and Safe

- Safety Gas Regulator

- NC Gas Solenoid

- Runs on Liquid Propane

- 6″ Exhaust

- Flameless

- 110V Power 20Amp

Testing and Results

H- Series :

Flash time: 10 min

Tack time: 10 min

Final Bake: 20 min

Cool down time: 8 minutes

PST: 180F

Adhesion – 5B

Pencil Hardness – 9H

C- Series :

Flash time: 10 min

Final Bake: 45 min

Cool down time: 8 minutes

PST: 290F

Adhesion -5B

Pencil Hardness -9H

Quench -1700f

Our Tech

Engineering Innovation

Your Service Here

Learn More

Your Service Here

Learn More

Your Service Here

Learn More

Your Service Here

Learn More

Your Service Here

Learn More

Your Service Here

Learn More

Your Service Here

Learn More

Your Service Here

Learn More

Gallery

Gallery of Excellence